Printing & Packaging Machinery

- MRS80 Mechanical Roll Stand MRS80 mechanical roll stand is capable of scrolling paper with maximum scroll size. For example, the bread breadth is 1.6 m × 1.3 m(diameter) and with minimum scroll of 0.8 m. The paper scroll is clamped, ascended, descended, moved left or right by electrical pressure. This mechanical roll stand is capable of holding...

- PH600 Pre-Heater and TPH600 Triple Pre-Heater The diameter of this pre-heater is Φ 600 mm.

The angle of contact is changed accordingly so as to adjust the heating area. Lantytk® Corp is a main supplier of corrugated paperboard production line (including pre-heater, single facer ...

- DGM80 Glue MachineDGM80 glue machine consists of press roller, paste roller and so on.

The press roller goes up and down through hydraulic system pneumatically.

Its position can be adjusted. The paste roller surface has netted lines and is coated with hardened chromium, which keeps the glue machine rotating after machine stopped. ...

- MSS80 Thin Blade Slitter Scorer The thin blade slitter scorer is characterized by thin cutting and auto blade sharpening. And the cutting and line pressing movement is driven by motor with its speed under auto monitoring. Besides, this slitter scorer machine is equipped with 4 blades and 6 lines. The cut specifications and line distances are manually adjustable. The press axel...

- FMQF Full Automatic High Speed Flute Laminator 1. FMQF Full Automatic High Speed Flute Laminator is available for continuous production from paper feeding to laminating, compressing and finally delivery to non-stop automatic down stacker. Maximum production speed can be as fast as 9000 sheet/hour. 2. Newly-designed single sheet flute laminating equipment with high automation...

- FMZ Automatic Flute Laminator1. Safety for user will be considered in the machine design. 2. Automatic feeding for face paper and bottom paper. 3. Easy operation & fault diagnosis can be provided during production by integrated control with PLC. 4. For the crucial function part of the automatic flute laminating machine, electrical parts adopt famous international brand of component like bearing...

- ZH-ZX2000/2400 automatic folder gluerThis automatic folder gluer is mainly applied to the carton gluing and folding, which is composed of three parts, that is, automatic feeder, automatic glue folding part and automatic count stacking part. Digital display speed control, PLC computer adjustment, dual-frequency synchronous operation, making the control mode of the machine simple, fast, reliable and precise...

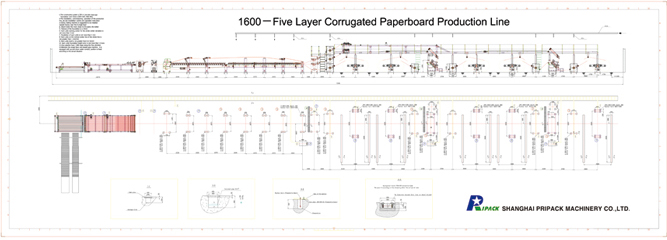

Working Process of Five-layer Corrugated Paperboard Production Line:

Parameters of Five-layer Corrugated Paperboard Production Line:

| Max. Machinery Speed | 100 m/min | |

| Working Speed | 60-70 m/min | |

| Max. Production Width | 1600 mm | |

| Paper Characteristics | Kraft Paper Face Paper | 125-360 g/m2 |

| Core Paper | 115-180 g/m2 | |

| Corrugated Flute Type | UV Type A , C, B, E Flute ( Optional ) | |

| Team Pressure and Consumption | 1.0-1.2 MPa 4 t/h | |

| Air Pressure and Consumption | 0.8-1.0 MPa 1.0 m3/min | |

| Power Source | 380 V 50 Hz | |

| The Total Capacity of the Installed Machine | About 160 kW | |

| Total Length of the Equipments | About 65 m ( Detailed Size Subject to the Foundation Drawing | |

| Binder | Starch Glue | |

Capability for Each Individual Unit of the Production Line

This five-layer corrugated paperboard production line is composed of four parts.

Part one mainly consists of MRS80 mechanical roll stand and SF260 single facer.

Part two is made up of PH600 pre-heater and TPH600 triple pre-heater and DBC80 bridge conveyor.

Part three includes DGM80 glue machine and DF14 double facer.

Part four is constituted by MSS80 thin blade slitter scorer and NCRC100 rotary cutter.

Lantytk® Corp is a professional supplier of corrugated paperboard production line in China, especially five-layer corrugated paperboard production line. This production line consists of four parts. Each part is composed of different machines and equipments. It is widely used in printing and packaging industry. Fore more information, please refer to our website and contact us directly.

- Roll Paper Sheet CutterThis CK series roll paper sheet cutter (paper roll to sheet cutter) is a kind of high speed paper process machine that is very popular in the paper making market.

Our CK series paper cutting machine adopts the advanced Germany and U.K technique. The machine can reach to a cutting speed as high as 350 sheets/min or 350 m/min, and ...

- Plate Exposure MachineThis plate exposure machine (automatic printing frame) uses 2mm cold rolling steel plate as main material. It is cord fabric full closed, features in stiff and smooth.

1. Computer program-controlled

2. Secondary pumping ...